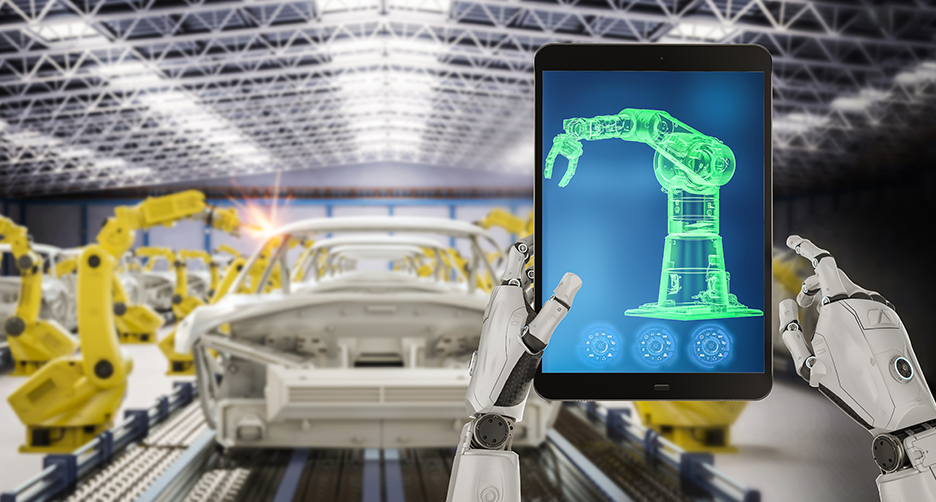

Products are becoming more and more innovative and the way they are manufactured must also be innovative.

Innovative digital manufacturing technologies link systems and processes in all areas of production enabling an integrated approach to manufacturing, from design to production and after-sales service of the final products.

Digital Manufacturing

Our Digital Manufacturing solutions will enable you to optimize manufacturing execution, from product design and innovation to production line improvement and resource optimization for better products and client satisfaction.

Our Services

All of our services are client-focused, resulting in a strong long-term relationship of trust. We are passionate and adaptable, and we accept our clients’ challenges as our own. That is why we offer solutions that are specific to each client’s needs.

We have 35 years of experience providing quality services with the highest commitment, responsibility, dedication, and technical excellence.

CT Solutions provides a wide range of engineering services throughout the product and asset life cycle. From concept to development. We have extensive knowledge and experience in the design, manufacturing, and maintenance processes.

Business consulting

- Process definition.

- Robotic simulation.

- Simulation of production and logistics systems.

- Selection of tools for digital manufacturing.

Implementation of Digital Manufacturing solutions

- Implementation of digital manufacturing solutions such as TECNOMATIX PROCESS SIMULATE, TECNOMATIX PLANT SIMULATION or DELMIA 3DEXPERIENCE ®.

- Integration with corporate systems (ERP, MES, etc).

- Updating of versions.

Implementation audit

- Evaluation of customization standardization possibilities.

- Usability analysis (functionality deployed vs. required).

- Performance and architecture analysis.

- Licensing study.

Post-implementation service

- Training in TECNOMATIX PROCESS SIMULATE, TECNOMATIX PLANT SIMULATION and DELMIA 3DEXPERIENCE ®.

- Technical assistance, user support and evolutionary maintenance.

- Technical office (operation support): robotic simulation and simulation of production and logistics systems.

in the following industries

- Transportation and Mobility

- Aerospace and Defense

- Industrial Machinery

- Naval Sector

- Packaging

- Energy and Utilities

- Electronics and Semiconductors

- Consumer Products

- Food and Beverages

- Health Sector